telephone

13710276321

Hello! Welcome to visitGuangzhou Mingrui Automation Equipment Co., Ltd

position:Home > Roll film packaging machine > Automatic weighing and packaging machine

180 packaging machine weighing elevator platform

Equipment introduction

This machine can automatically complete the entire process of loading, measuring filling date printing, bag making, sealing and other packaging It can automatically count the packaging and achieve the set output with automatic shutdown prompts. The system is equipped with fault alarm reminders to help timely troubleshoot and truly achieve fully automatic production packaging.

Packaging process: film pulling - coding - bag making - measurement - filling (inflation) - sealing (punching) - cutting - finished product output.

Scope of application: Automatic quantitative packaging of granular, flake, strip, block, spherical, powder, and liquid materials;

Bag making form: back sealed bag, back sealed corner bag, three side seal, four side seal, striped seal, mesh seal;

Packaging materials: PP, PE, PVC, PS, EVA, PET, PVDC+PVC, OPP+composite CPP, etc;

Quantitative device: measuring cup, combination scale, linear scale, screw, liquid pump, counting tray, hopper conveyor line, etc;

Optional functions: nitrogen filling, exhaust, vacuum pumping, punching circular holes, punching butterfly holes, connecting packages, and other functions.

Performance characteristics

Chinese and English human-machine interface, touch screen display control, intuitive, simple and convenient operation;

For particles, powders, and liquid materials, corresponding measuring devices can be optionally equipped to achieve precise and efficient measurement;

(The above functions are already included as standard in the packaging machine program)

The whole machine adopts three servo control systems: stable and reliable operation, low noise, fast speed, and high efficiency;

Servo drive is used for film pulling and releasing: ensuring precise film pulling and neat and beautiful packaging bag shape effect;

The core components have been specially optimized and designed to operate smoothly;

The electrical components adopt domestic and international first tier brands, and have been tested by years of market practice, which are durable, stable and reliable;

The entire machine is assembled using 3mm and 5mm thick SUS304 stainless steel sheet metal processing, which is easy to clean and prevents cross contamination;

The overall design of the machine complies with GMP standards and has passed CE certification, meeting the requirements of food and drug production.

technical parameter

entry nameSpecification parameters

Packaging speed80-110Bag/minute(Related to packaging materials and filling materials)

Measuring cup capacitycustomization:10-500ml、Adjustable±30%

Weighing range2-300g,accuracy ±0.2-1g

Sealing styleStraight lines(spacing 1.5mm)Tooth cutting horizontal and vertical sealing width 10mm

Bag Size L(50-180)mm x W(50-150)mm

Roll width120-320mm

Film thickness0.05-0.12mm

Power supply powerAC220V 50Hz 4KW

Gas consumption0.6-0.8Mpa 100-200L/min

External dimensionsPackaging machineL1350*W900*H1400mm(Measuring cup2350mm)All-in-one machine2.3m、weighing2.5m、powder2.50m、liquid1.8m

Overall weightPackaging machine350kg(Weigh the entire set800kg)

Equipment modelServo turntable measuring cupMR-320G Swing rod measuring cup

MR-320S Powder packaging machine

MR-320P Liquid sauce packaging machine

MR-320L

Packaging speed80-100Package/minute60-100Package/minute30-100Package/minute10-40Package/minute

Packaging scope5-500g2-50g5-500g10-500g

Quantitative accuracy±0.5-2g±0.1-0.5g±0.3-1%±0.5-1%

Bag Size L(50-200)mm x W(50-150)mm

Film specificationswidth120-320mm,thickness0.05-0.12mm

Power supply powerAC220V 50Hz 4KW

compressed air0.6-0.8Mpa 0.2m³/min

External dimensionsL1.3*W0.9*H2.2mL1.3*W0.9*H1.8mL1.3*W0.9*H2.3mL1.3*W0.9*H1.8m

Overall weightPackaging machine500kg500kg550kg500kg

Device picture Dimensions

1. Equipment style reference diagram: measuring cup (top left), liquid (top right), weighing (bottom left), powder (bottom right)

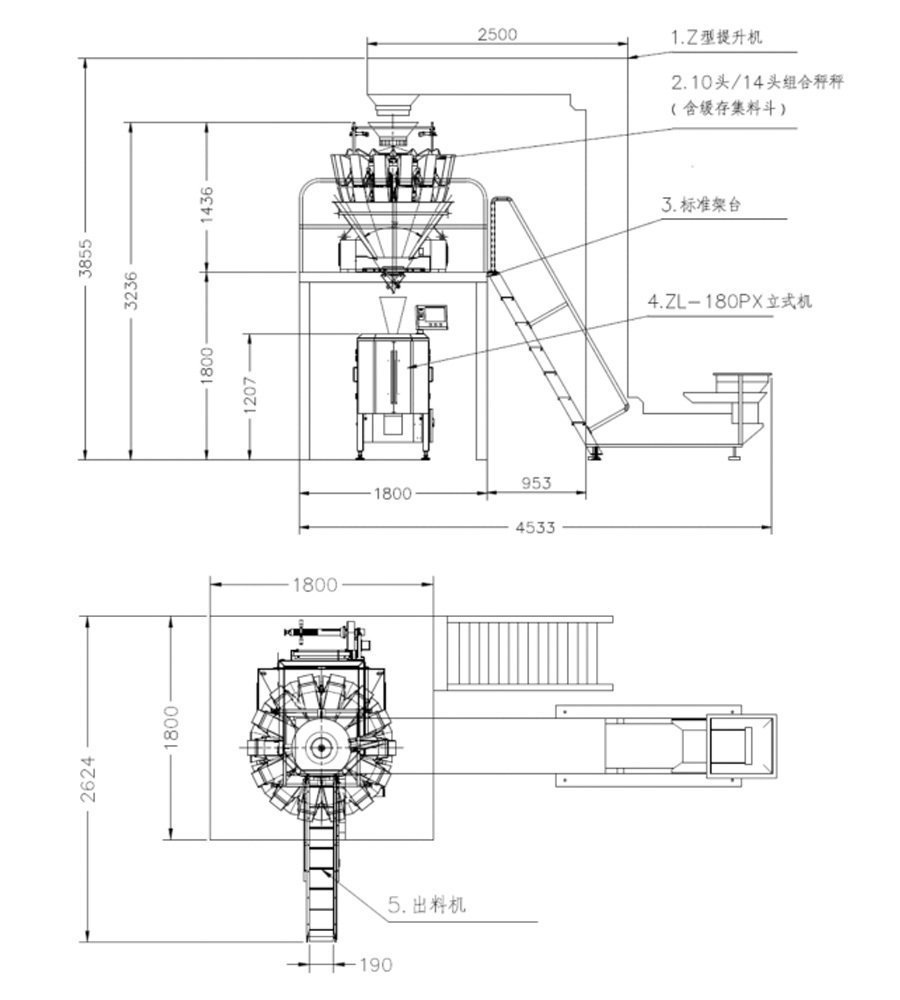

2. Equipment dimension diagram: weighing+packaging

3. Equipment dimension diagram: measuring cup+packaging machine

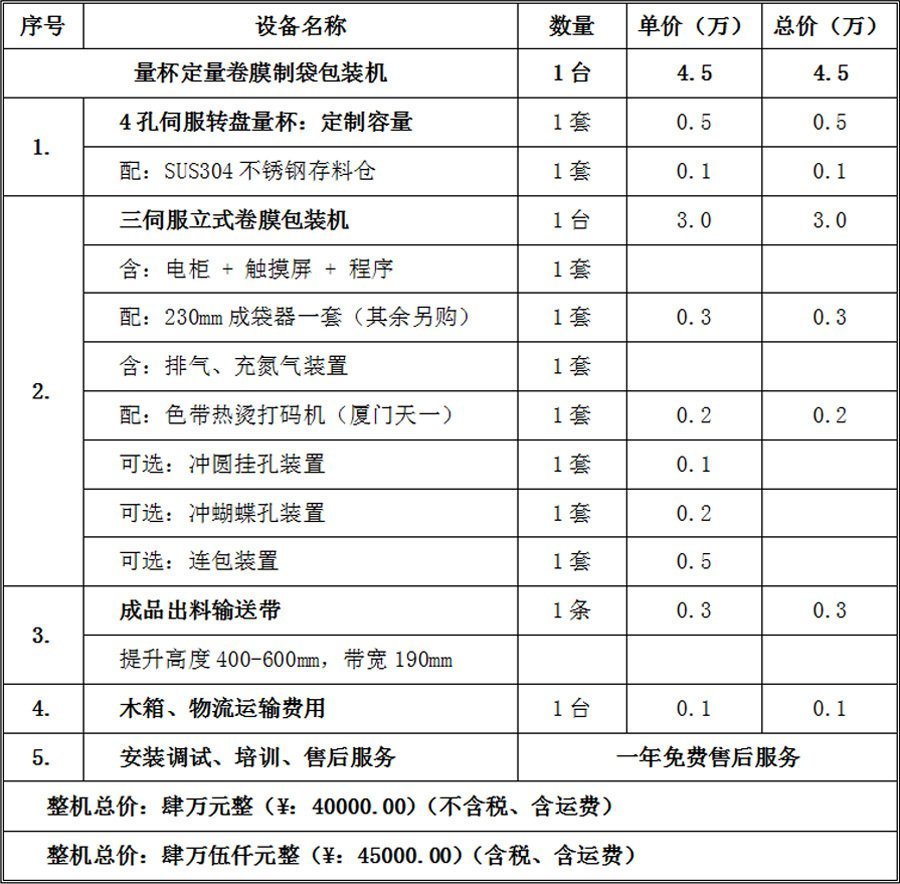

Parts configuration

Configuration details

Delivery date

1. Settlement method:

After both parties sign the contract, the buyer shall pay 60% of the deposit first, and 40% of the payment before shipment.

2. Delivery deadline:

Both parties sign a contract and ship within 15 days from the date of receiving the deposit.

3. Delivery location:

The seller is responsible for delivering all equipment to the location designated by the buyer, and the cost shall be borne by the seller.

The buyer is responsible for unloading and hoisting the equipment during installation, and pays the relevant fees

Previous:Integrated machine

Next:没有了