telephone

13710276321

Hello! Welcome to visitGuangzhou Mingrui Automation Equipment Co., Ltd

position:Home > Vacuum packaging machine > Six sided shaping vacuum packaging machine

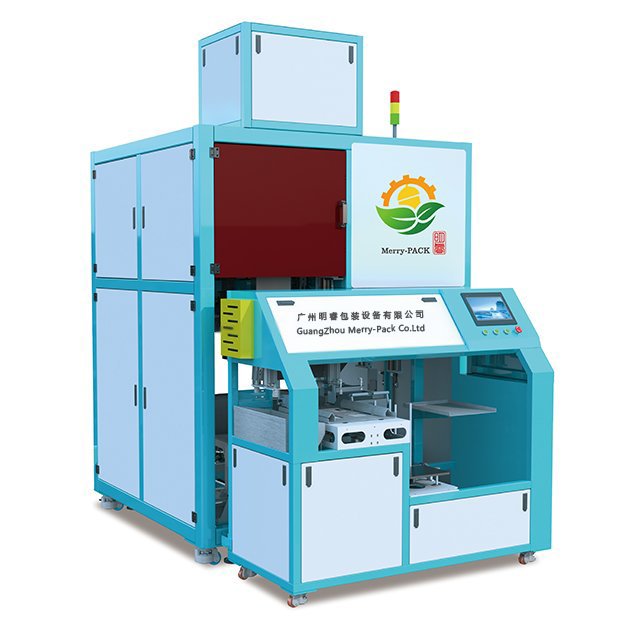

Full-Auto Six-Sided Vacuum Shaping Packing Machine

Scope of application

Suitable for six sided vacuum packaging of small particles or powder materials such as nuts, grains, yeast, chemical raw materials, etc.

Packaging sample

Technical Parameters

Device NameFully automatic six sided two station fully automatic six sided four station semi-automatic two station, six sided semi-automatic four station, six sided

Equipment modelMR-ZB-Z2MR-ZB-Z4MR-ZB-B2MR-ZB-B4

Weighing accuracy±1-5g,X(0.5)±1-5g,X(0.5)±1-5g,X(0.5)±1-5g,X(0.5)

Packaging range300g-5kg300g-5kg300g-5kg300g-5kg

Packaging speed500-700 bags/h1000-1200 bags/h500-700 bags/h Six sided: 300-360 bags/h两面:200-250包/h

Rice brick sizeLength:160-350mm

Width:60-250mm

Thickness35-90mm length:160-350mm

Width:60-250mm

Thickness35-90mm length:160-350mm

Width:60-250mm

Thickness35-90mm length:160-350mm

Width:60-250mm

Thickness35-90mm

Vacuum pumping degree-0.07Mp-0.0Mp-0.07Mp-0.0Mp-0.07Mp-0.0Mp-0.07Mp-0.0Mp

Power supply powerThree-phase five wire AC380V 50Hz 5.3KW three-phase five wire AC380V 50Hz 8.5KW three-phase five wire AC380V 50Hz 2.5KW three-phase five wire AC380V 50Hz 3.5KW

Gas consumption0.6-0.8Mpa 20㎥/h0.6-0.8Mpa 30㎥/h0.6-0.8Mpa 10㎥/h0.6-0.8Mpa 20㎥/h

External dimensionsL1.7m*W3.0m*H2.8mL2.5m*W3.0m*H2.8mL1.6m*W2.6m*H2.0mL2.7m*W2.6m*H2.0m

Functional features

Using a 14 head electronic combination scale for weighing, it has high accuracy, fast speed, good stability, and wide material adaptability;

Dual station independent operation: One side failure does not affect production on the other side,

Mold replacement is simple and fast: no tools are needed, and mold replacement can be completed within five minutes;

Adopting advanced storage bag design, it can store 200-300 bags at once

Automatic removal of abnormal bags function: Even if there is a bag problem, the equipment will continue to operate uninterrupted;

The bag layered isolation recognition technology effectively solves the problems of bag curling causing failure to load the bag;

The internal part of the material receiving box in contact with the material is made of soft materials to prevent damage to the vacuum formed packaging bag,

Adopting a bucket flip discharge mode to protect the vacuum packaged finished bags from damage;

All translation components are equipped with linear guides, which operate stably and have a long service life;

All driving components of the equipment are equipped with cylinders and motors, which are environmentally friendly, clean, and pollution-free;

All parts in contact with materials are made of 304 stainless steel or food grade silicone;

The new electrical design process can significantly extend the service life of the heating control system;

Imported power supply filtering processing effectively eliminates the impact of other machines in the factory on equipment;

Imported power phase sequence protection device to completely prevent motor reversal from damaging equipment;

Pay more attention to equipment safety and use imported anti loosening and anti electric shock wiring terminals;

Cloud based IoT technology, equipped with remote monitoring modules, allows for anytime, anywhere understanding of production situations;

The device has a fault self check function, which can quickly troubleshoot based on the touch screen prompts.

Optional: desiccant or deoxidizer automatic feeding machine, metal detection machine, secondary weight detection scale.

Previous:没有了