telephone

13710276321

Hello! Welcome to visitGuangzhou Mingrui Automation Equipment Co., Ltd

position:Home > Drum film packaging machine > Three station drum film packaging machine

Tube film Packing Machine MR-TF500

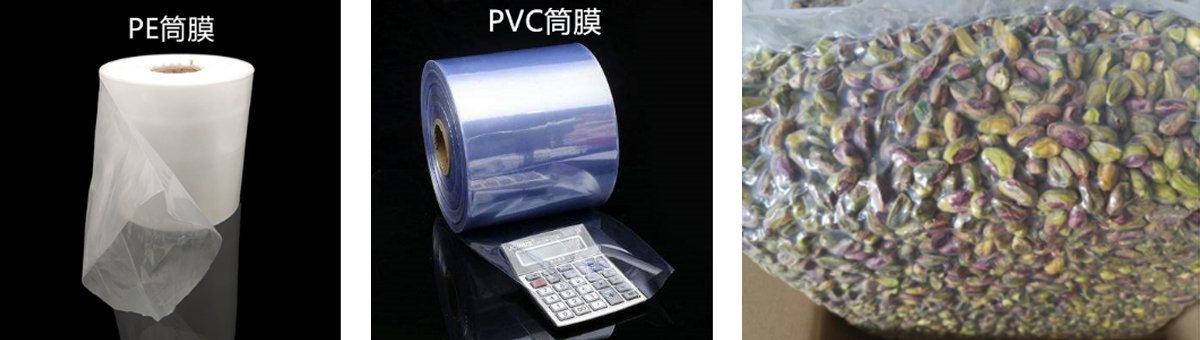

The drum film packaging machine is a type of packaging machine that uses cylindrical PE film and can automatically complete: bag making, coding and labeling, metering and filling, inflation and exhaust, shaping and sealing.

Compared with traditional vertical film packaging machines, its biggest advantage is that it directly uses cylindrical film, and when the top and end of the bag are cut and sealed, it is made into a bag. Because there is no need to use a collar shaper to shape bags, the hassle of replacing the shaper is eliminated when switching bags of different widths. Simply replace the drum film of different widths.

Another important advantage of the drum film packaging machine is that when packaging bags with a width of more than 200mm, the equipment can be very low by 800-1200mm, while the height of the vertical roll film packaging machine can easily exceed 1800mm, which requires higher net height in the packaging workshop. Moreover, for operators, daily tasks such as film replacement and adjustment, the drum film packaging machine is easier to operate and maintain.

The drum film packaging machine is an easy-to-use multifunctional packaging machine that is suitable for products of different weights and sizes, such as furniture accessories, machine parts, electronic components, food and medicine, and dried fruits.

The machine can adopt a semi-automatic packaging method of manual feeding, and can also be equipped with various automatic measuring devices, such as multi head scales, linear scales, measuring cups, particle counting machines, bucket conveyor lines, powder screw measuring scales, liquid paste pumps, etc., to form a complete set of fully automatic packaging machines.

The three station drum film packaging machine is the latest patented equipment developed by Guangzhou Mingrui. Most drum film packaging machines on the market are single station, and all packaging actions need to be completed in the same station of the machine before packaging the next package of products. The packaging speed is slow. After redesigning the entire packaging action, it is decomposed into three independent stations: film pulling and sealing bag making, bag opening and filling inflation vacuum pumping, and sealing output. The packaging speed is 2-3 times faster than single station drum film packaging machines.

work technological process

Drum film pulling -->reaching the set bag length (touch screen setting, encoder fixed length) -->front sealing knife sealing -->cutting knife action -->completing a bag making -->moving the bag clamp to the feeding station -->opening and dropping -->material completion -->bag opening straightening -->shaping and vacuuming -->rear sealing knife sealing -->finished product transportation.

Advantages and characteristics

*Three workstations: independent work for bag making, filling, and sealing, with fast packaging speed;

*Self diagnosis of unsuccessful (or incomplete) bag disconnection and failure to dispense and fill;

*Packaging shaping: tapping the bottom of the bag, sorting materials and sinking them to the bottom of the bag;

*Compatible with a wide range of bag widths, easy to change, and easy to adjust;

*Door opening and shutdown: safety door switch alarm;

Optional function

*Vacuum pumping device: Vacuum pumping

*Protective clip device: an essential auxiliary facility for inflation or extraction, to prevent materials from splashing out from the bag opening (powder and liquid) during loading;

Automatic packaging machine: desiccant, deoxidizer

Secondary weight inspection belt scale

Metal detection machine

Technical Parameters

Packaging speed5-10bag/min

Weighing accuracy±2-10g

Weighing range1-10kg

Bag sizeL300-600mm, W250-500mm

Sealing knife width2-5mm

Voltage powerAC220V 50Hz 4KW

Gas source requirement0.4-0.8MPa 0.5m³/min

Body size5000×2500×4000(长×宽×高)

Total weight1200kg

Packaging sample

Previous:Single station drum film packaging machine

Next:没有了